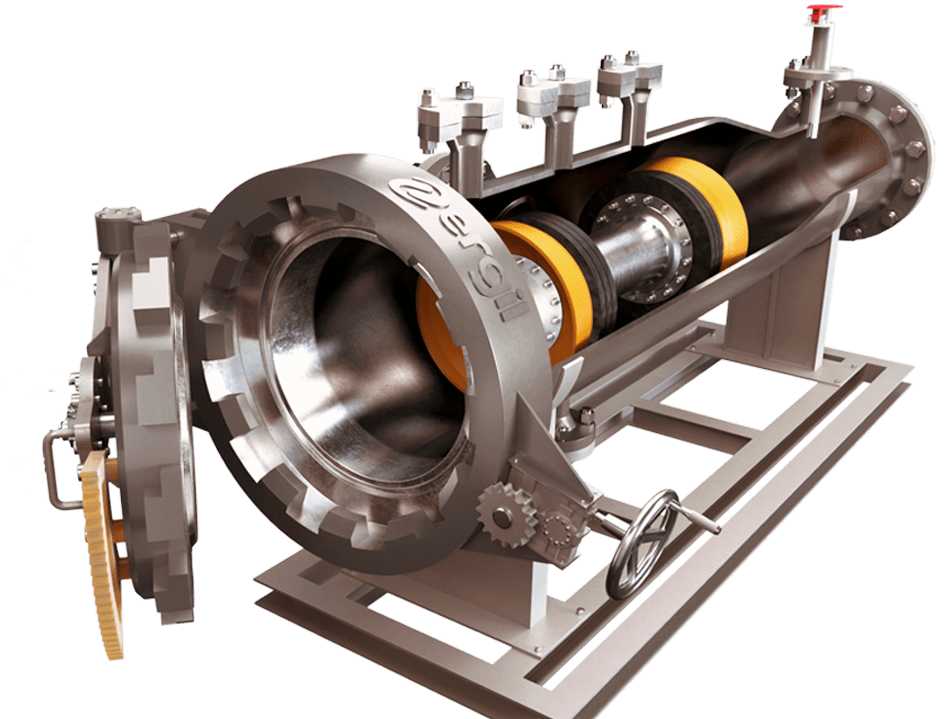

MONOLITHIC ISOLATION JOINTS

Wherever you find oil and gas pipelines , you also find a wide array of reliable ALFA Pipeline Products isolation joints.The correct location of monolithic isolation joints helps to reduce the overall cost of corrosion control systems and save millions of dollars by improving eficiency against corrosion problems

FOR ONSHORE PROJECTS

- To limit the spread and hence the cost of cathodic protection to those pipelines that need to be effectively and economically protected by the main cathodic protection system

- To electrically “split-up” long pipelines into distinctive cathodic protection system.

- To isolate a pipeline and ensure that cathodic protection or stray electricity currents do not cause increased corrosion.

- To provide protection against earthing currents at domestic and industrial premises where the PME system is in use.

FOR OFFSHORE PROJECTS

- In riser pipes and offshore structures to isolate the pipeline cathodic protection system.

- At field “tie-ins”.

ELECTRIC FEATURES

- Electric insulation resistance ≥ 200 MΩ.

- Dielectric strength 5 ~ 12 kV A.C 50 Hz